Reducer

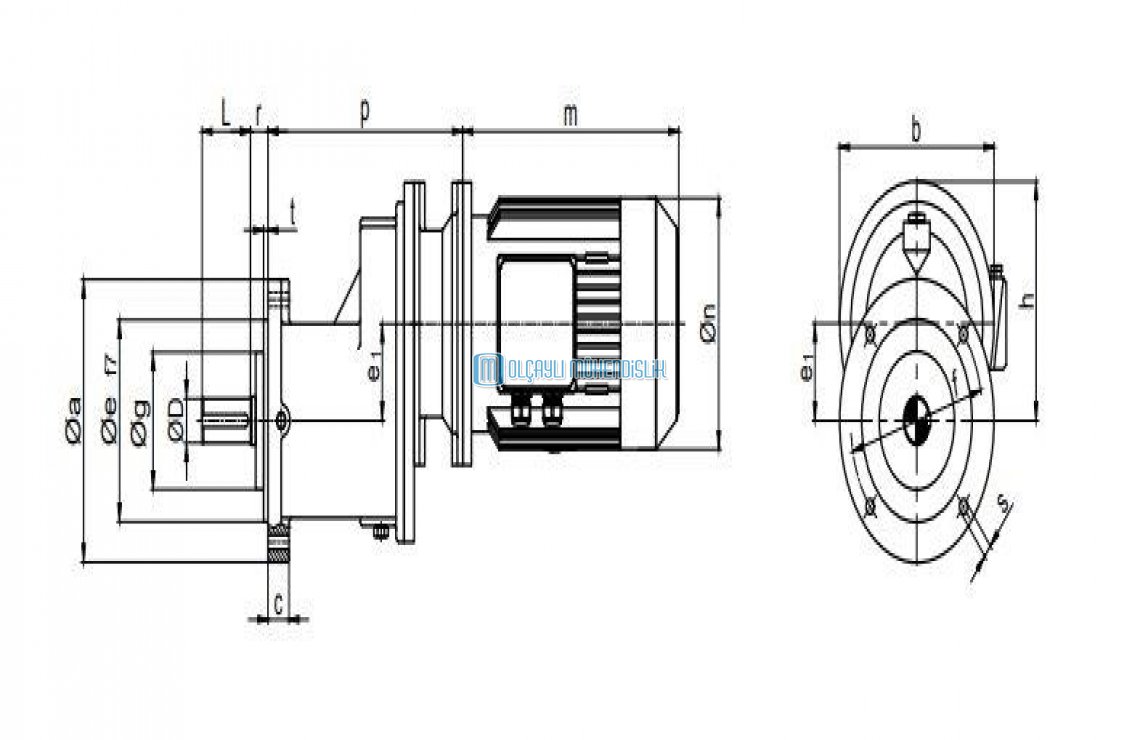

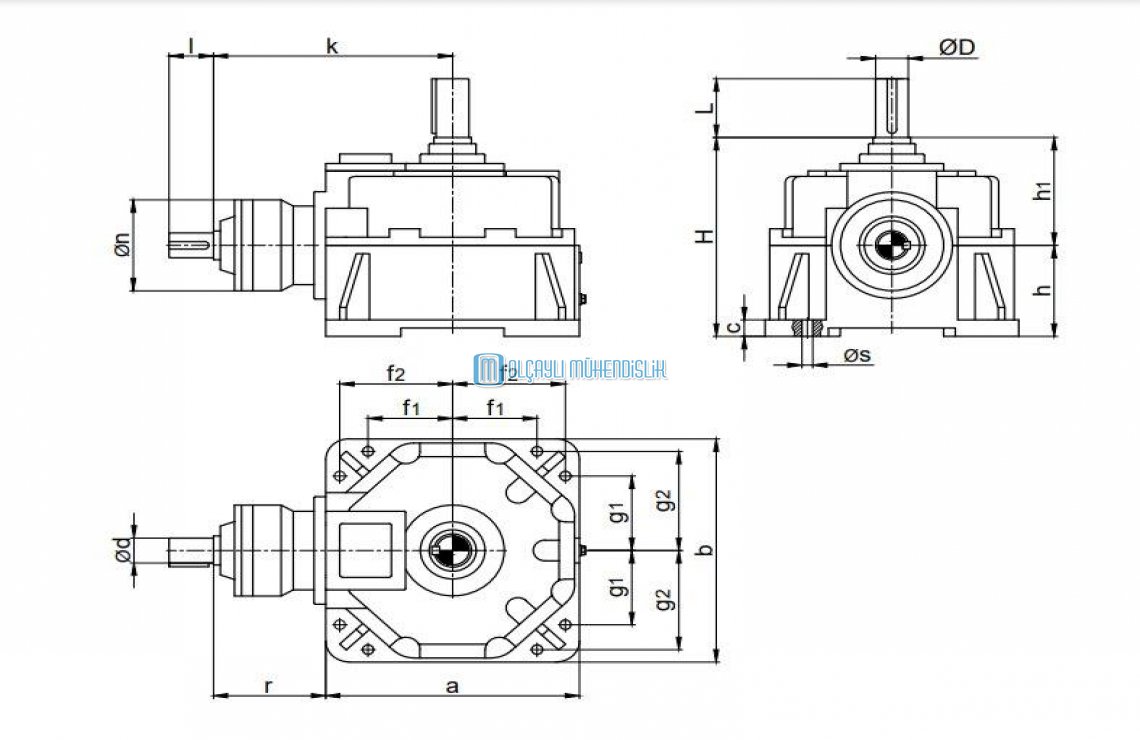

| Housing |

Housings are made from GG20 cast iron and machined on CNC machining centers. |

| Gears | Gears are produced from high quality alloy steel. They are precision machined, case hardened to HRC 58-60 and precision ground to ensure a quiet and low vibration operation of the gear unit. |

| Shafts | Input shafts are pinion gear shafts and are produced from alloy steel. Solid output shafts are produced from C45 carbon steel. The keys and key ways on the shafts are machined according to DIN 6885/1. |

| Bearings | Tapered roller bearings are used. The bearing selection is made to ensure a lifetime of min 100,000 hours. |

| Oil Seals | High quality input and output oil seals are used to prevent oil leakage from inside and to keep outside contamination from entering the gear unit. Additionally, the labyrinth type umbrella with o-ring system on the output shaft provides extra protection against contamination entering the gear unit. |

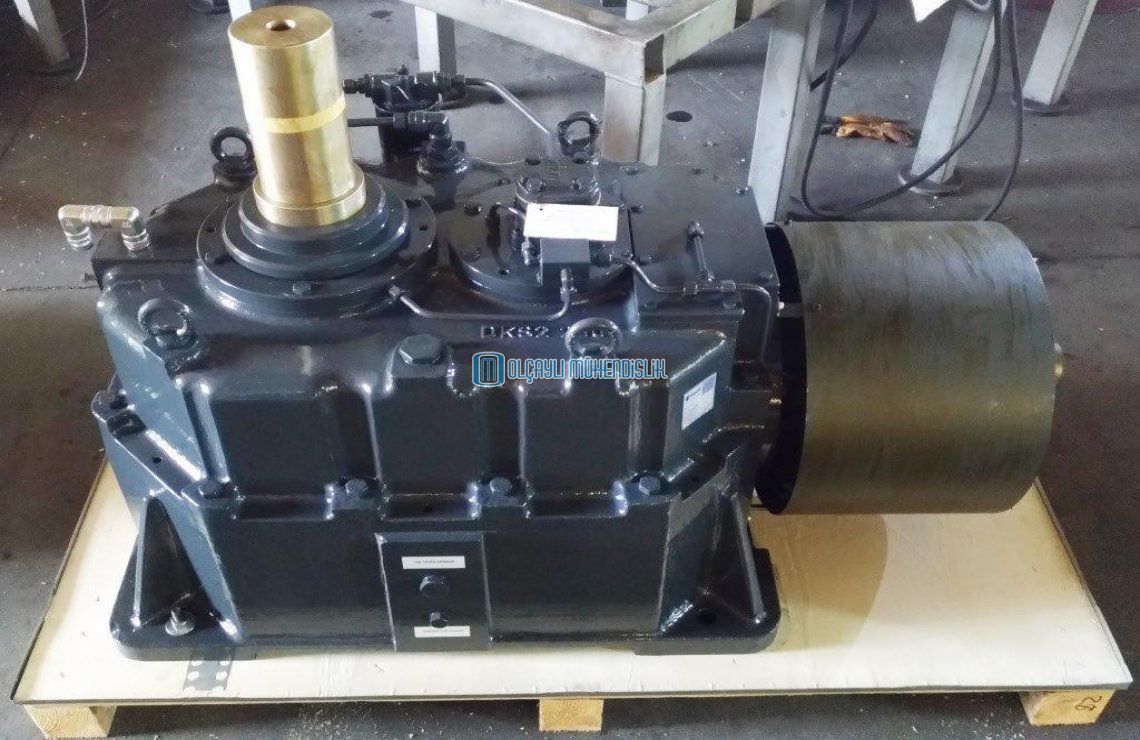

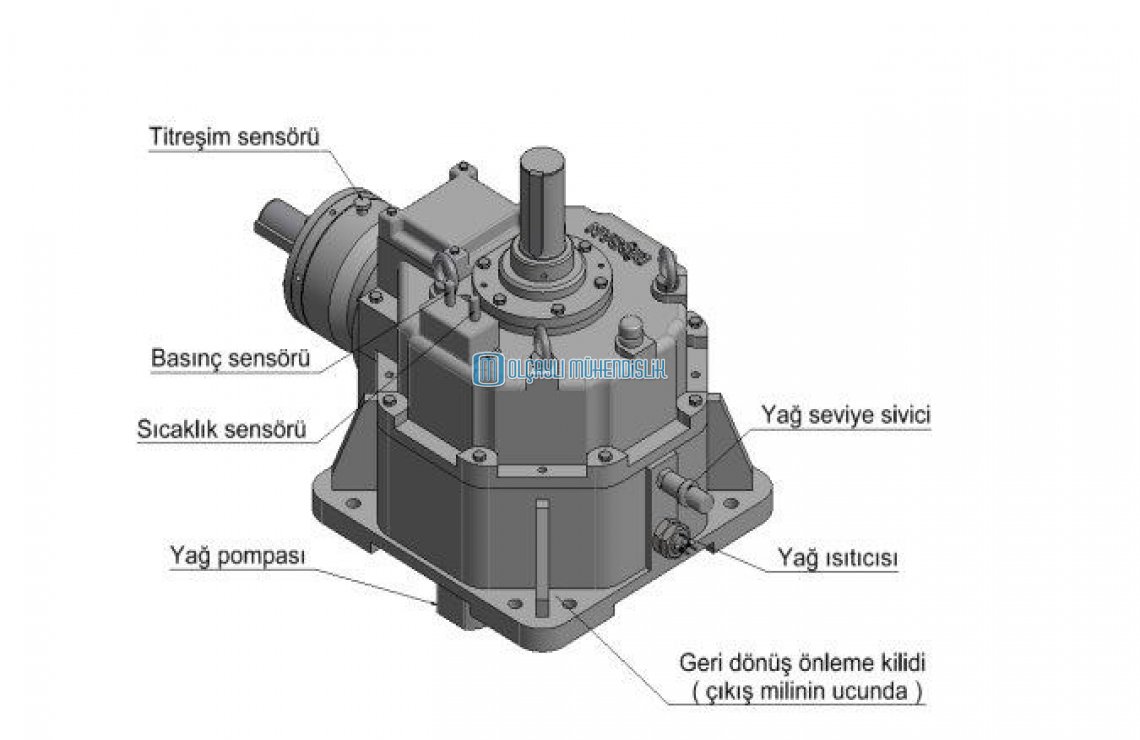

| Lubrication | Gear units are lubricated with oil bath splash method. In case of high powers, forced lubrication with oil pump is also used as standard. |

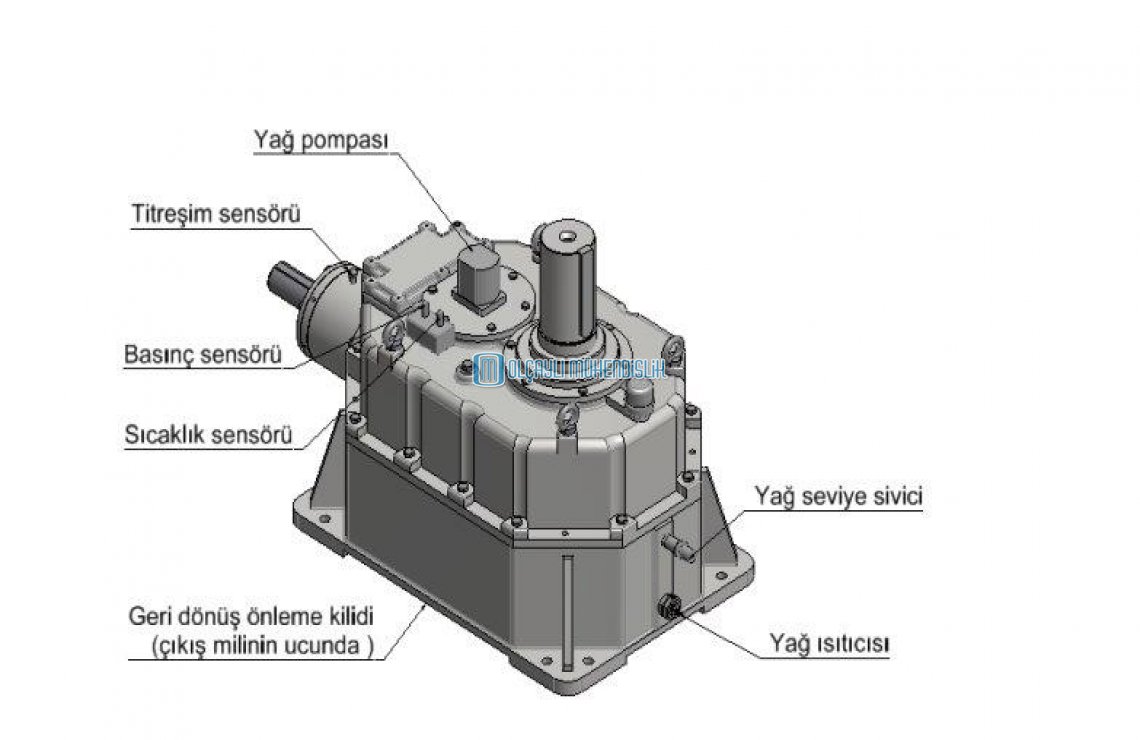

| Optional | Back-stop, oil level switch, oil temperature sensor, vibration sensor, pressure sensor, oil heater with thermostat, oil dip stick, oil pump. |

The working principle of a reductor is like a gear reducer in a water cooling tower can be explained as follows:

- Speed Reduction: The primary function of a gear reducer is to reduce the high speed generated by the electric motor to a lower, more suitable speed for driving the fan or other equipment in the cooling tower. This reduction in speed is achieved through a set of gears inside the gearbox.

- Gearing System: The gearbox contains multiple gears of different sizes arranged in a specific configuration. When the motor spins at a high speed, the gears inside the gearbox interlock, transmitting motion from the input shaft connected to the motor to the output shaft connected to the fan or other rotating components.

- Torque Increase: While the speed is reduced, the gear reducer increases the torque, which is the rotational force applied to the fan blades or other components. This increase in torque is necessary because it allows the fan to exert sufficient force to draw air through the cooling tower, especially against the resistance created by the airflow and water pressure.

- Enhanced Efficiency: By adjusting the gear ratio, the gear reducer ensures that the fan operates at an optimal speed, maximizing the efficiency of the cooling tower. This optimal speed is determined based on the cooling tower's design requirements, the cooling load, and the specific application.

- Direction Control (Optional): Some gear reducers allow for changes in rotational direction. This feature is useful in applications where the fan needs to operate in both clockwise and counterclockwise directions, depending on the system requirements.